What is the difference between LNG and CNG?

Contents

What is the difference between LNG and CNG?

Contents1 Orifice Pressure Drop Calculator1.1 Orifice pressure drop Equation1.2 example of orifice pressure drop calculation1.2.1 Given Data1.2.2 Conclusion1.3 What is an Orifice Pressure Drop?1.3.1 How It Occurs1.3.2 Practical Applications1.4 Effects of Orifice Pressure Drop1.4.1 1. Flow Measurement Accuracy1.4.2 2. Energy Loss1.4.3 3. System Pressure Requirements1.4.4 4. Fluid Dynamics1.4.5 5. Wear and Tear1.4.6 6. Cavitation and […]

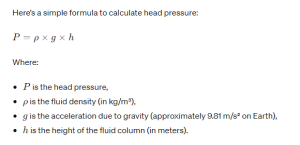

Contents1 Head Pressure Calculator2 Head Pressure Calculator Equation3 What is 20 feet of head pressure?3.1 Calculation: Head Pressure Calculator Head Pressure Calculator Density (kg/m³): Height of Fluid Column (m): Calculate Pressure Head Pressure Calculator Equation To create a head pressure calculator, we first need to clarify a few details. Head pressure in fluid mechanics […]

Contents1 Is 304 stainless steel magnetic ?2 What is is 304 stainless steel ?3 304 stainless steel specifications3.1 Chemical Composition3.2 Mechanical Properties3.3 Physical Properties3.4 Corrosion Resistance3.5 Formability and Weldability4 Comparing 304 stainless steel with others material4.1 1. 304 Stainless Steel vs. Carbon Steel4.2 2. 304 Stainless Steel vs. Aluminum4.3 3. 304 Stainless Steel vs. 316 […]

Contents1 Is stainless steel magnetic ?2 Types of stainless steel and stainless steel magnetic3 What is Stainless Steel?4 Stainless Steel Chemical Composition4.1 1. Austenitic Stainless Steels4.2 2. Ferritic Stainless Steels4.3 3. Martensitic Stainless Steels4.4 4. Duplex Stainless Steels4.5 5. Precipitation-Hardening Stainless Steels5 Properties of Stainless Steel6 Stainless Steel Standards and Specifications7 Application of Stainless Steel […]

Contents1 Psi vs Psig Conversion2 What is psi ?3 What is psig ?4 PSI vs PSIG: What’s their Difference5 What is the difference between the units psi and psig?6 Application of psi and psig6.1 PSI (Pounds per Square Inch)6.2 PSIG (Pounds per Square Inch Gauge) Psi vs Psig Conversion Converting between PSI (pounds per square […]

Contents1 What is the difference between a ball valve and a gate valve?1.1 Key Differences1.2 Ball Valve1.3 Gate Valve2 Table compare the difference between a ball valve and a gate valve3 The differences between a ball valve and a gate valve in specification3.1 Ball Valve Specifications3.2 Gate Valve Specifications3.3 Common Differences in Specification4 The key […]

Contents1 What is the difference between 316 and 316l ?2 Table compare Chemical Composition between 316 and 316L3 Which is better 316 or 316L?3.1 316 Stainless Steel3.2 316L Stainless Steel3.3 Decision Factors4 Is 316L more expensive than 316? What is the difference between 316 and 316l ? The difference between 316 and 316L stainless steel […]

Contents1 What is the difference between 316 and 304 stainless steel2 How to identify difference between 316 and 304 stainless steel2.1 1. Magnet Test2.2 2. Molybdenum Test Kit2.3 3. Nitric Acid Test2.4 4. Spark Test2.5 5. Laboratory Analysis2.6 Precautions3 Application 316 and 304 stainless steel3.1 304 Stainless Steel Applications3.2 316 Stainless Steel Applications What is […]

Automation System

Automation System  Energy Engineeing

Energy Engineeing  Instrumentation System

Instrumentation System  Mechanical Engineeing

Mechanical Engineeing  Piping Technologies

Piping Technologies  Transportations

Transportations  Manufacturing

Manufacturing  Training Material

Training Material