Instrumentation System

What is an Instrumentation System?

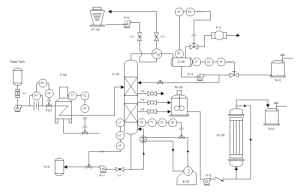

An instrumentation system refers to a comprehensive assembly of devices and components designed to measure, monitor, control, and regulate variables within a process or environment. These systems are pivotal in ensuring the accuracy, efficiency, and safety of industrial operations, scientific research, environmental monitoring, healthcare, and many other fields.

Instrumentation systems are integral to the modern industrial landscape, serving as the eyes and ears of various processes and operations. These systems provide critical data on parameters such as temperature, pressure, flow, and level, enabling precise control and optimization of industrial processes. Their role spans across numerous sectors, including manufacturing, environmental monitoring, healthcare, and aerospace, underscoring their versatility and importance.

Instrumentation systems are pivotal in the seamless operation and monitoring of complex industrial processes, playing a crucial role across a myriad of sectors including manufacturing, healthcare, environmental management, and aerospace. These systems, comprising an intricate network of fitting , valves,tubings, flexible hose ,sensors, actuators, control systems, and data acquisition units, facilitate the precise measurement and control of various physical quantities such as temperature, pressure, flow rate, and chemical composition. Instrumentation systems stand as the cornerstone of process optimization, ensuring efficiency, safety, and reliability. As we delve into the intricacies of these systems, we will explore their components, types, applications, technological advancements, and the challenges faced in the field. This article aims to provide a comprehensive overview of instrumentation systems, shedding light on their significance in advancing industrial capabilities and improving quality of life.

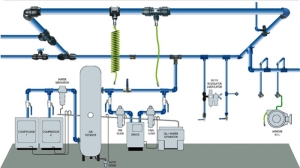

Core Components of an Instrumentation System

Instrumentation systems are complex assemblies that rely on numerous components to measure, control, and regulate various industrial processes. Beyond the primary devices like sensors and actuators, the integrity of an instrumentation system is also upheld by its foundational elements such as tubing, fittings, valves, regulators, hoses, and measurement devices. Each of these components plays a crucial role in the accurate and efficient functioning of the system.

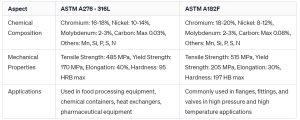

Tubing

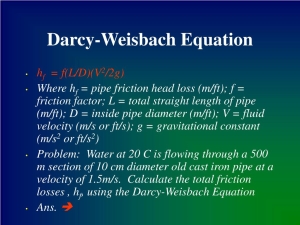

Tubing is a critical component in instrumentation systems, serving as conduits for fluids and gases. Made from materials like stainless steel, copper, and plastic, tubing must be chosen based on the specific requirements of the system, including pressure ratings, temperature ranges, and chemical compatibility. Precision in tubing selection and installation is vital to prevent leaks, pressure drops, and contamination, ensuring the safe and efficient transport of media.

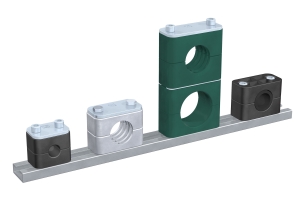

Fittings

Fittings are used to connect tubing sections, components, and instrumentation devices within the system. They come in various shapes, sizes, and materials, including elbows, tees, reducers, and unions, each designed for specific applications. The selection of fittings involves considerations of pressure and temperature ratings, compatibility with tubing materials, and the type of sealing required to maintain system integrity.

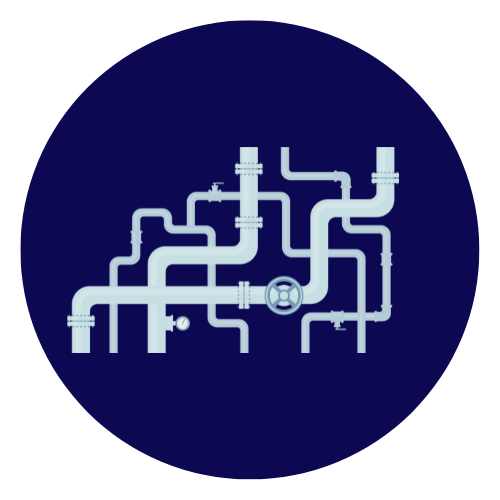

Valves

Valves are essential for controlling the flow of fluids and gases within an instrumentation system. They can regulate flow rates, direct flow paths, and isolate sections of the system for maintenance or in emergency situations. Valves come in many types, such as ball, gate, globe, and check valves, each offering different characteristics in terms of flow control, pressure drop, and leak tightness. The choice of valve type and material is crucial for ensuring compatibility with the process media and the operational conditions.

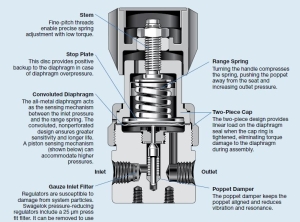

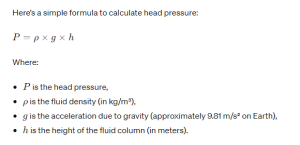

Regulators

Regulators maintain the pressure within an instrumentation system, ensuring that it remains within specified limits. They are vital for the protection of sensitive components and for the accuracy of measurements and control actions. Pressure regulators can be designed to maintain constant outlet pressure despite variations in inlet pressure or to maintain a constant differential pressure across a system component.

Hoses

Hoses provide flexible connections between components in an instrumentation system. They are particularly useful in applications where movement or vibration is expected, or where rigid tubing cannot be easily installed. Hoses must be selected based on their pressure ratings, flexibility, and material compatibility with the process media. They are typically reinforced with materials like steel or synthetic fibers to withstand high pressures and harsh operating conditions.

Measurement Devices

Measurement devices, such as gauges, transmitters, and analyzers, are the eyes of an instrumentation system, providing data on parameters like pressure, temperature, flow rate, and chemical composition. These devices can be analog or digital, with digital instruments offering advantages in terms of accuracy, data logging, and remote monitoring capabilities. The selection of measurement devices depends on the precision required, the nature of the measured parameter, and the environmental conditions.

Sensors

Sensors detect changes in physical conditions or the presence of specific substances and convert these changes into measurable signals. For example, a temperature sensor might use a thermocouple to detect temperature changes and convert them into electrical signals.

Transducers

Transducers convert one form of energy into another, facilitating the processing of sensor signals. They play a crucial role in converting the physical quantities detected by sensors into standardized signals that can be interpreted by control systems.

Actuators

Actuators are the action components of instrumentation systems. They respond to control signals by altering physical conditions. For instance, a valve actuator might open or close a valve based on the control signal it receives, regulating the flow of a fluid.

Control Systems

These are the brains of the operation, interpreting signals from transducers and determining appropriate responses, which are then executed by actuators. They range from simple manual controls to complex automated systems that can adjust operations in real-time based on sensor data.

Together, these components form a cohesive system capable of monitoring, controlling, and optimizing industrial processes, ensuring efficiency, safety, and reliability in operations.

Types of Instrumentation Systems

Instrumentation systems are integral to various fields, providing critical data for process control, ensuring safety, and facilitating research and development. These systems can be broadly categorized into process control systems, electrical measurement systems, biomedical instrumentation, and environmental monitoring systems. Each category serves distinct purposes and is tailored to meet the specific requirements of different industries.

Process Control Systems

Process control systems are pivotal in industrial settings, where they maintain the desired output of a process through careful measurement and control of variables like temperature, pressure, flow, and level. These systems ensure the efficient and safe operation of manufacturing plants, refineries, and chemical processing facilities. By employing sensors and actuators, process control systems can automatically adjust process variables to maintain setpoints, thereby optimizing production rates, enhancing product quality, and minimizing waste. Advanced systems incorporate distributed control systems (DCS) and programmable logic controllers (PLC) for greater flexibility and scalability, allowing for sophisticated process management and real-time operational adjustments.

Electrical Measurement Systems

Electrical measurement systems are specialized in assessing various electrical parameters such as voltage, current, resistance, capacitance, and inductance. Utilized extensively in the design, testing, and maintenance of electrical equipment and circuits, these systems ensure the functionality and safety of electrical devices. From simple multimeters to complex automated test equipment (ATE), electrical measurement systems cover a wide range of applications. High-precision instruments like oscilloscopes, function generators, and network analyzers play a crucial role in research and development, enabling the fine-tuning of electronic components and systems for optimal performance.

Biomedical Instrumentation

Biomedical instrumentation encompasses a vast array of technologies designed to monitor, diagnose, and treat medical conditions. These systems range from simple devices like thermometers and blood pressure cuffs to advanced imaging equipment like MRI and CT scanners. Biomedical instruments play a critical role in patient care, enabling healthcare professionals to obtain vital signs, visualize internal structures, and understand physiological functions. Innovations in this field, such as wearable health monitors and implantable devices, are revolutionizing patient care by providing continuous, real-time health data, facilitating early detection of abnormalities, and enabling personalized treatment plans.

Environmental Monitoring Systems

Environmental monitoring systems are essential for assessing the health of our planet, tracking changes in air quality, water purity, soil composition, and biodiversity. These systems employ a network of sensors and data loggers to collect information on various environmental parameters, including temperature, humidity, particulate matter, and pollutant concentrations. This data is crucial for understanding the impact of human activities on the environment, informing policy decisions, and guiding conservation efforts. Advanced environmental monitoring systems leverage satellite imagery and remote sensing technologies to provide comprehensive and global coverage, enabling the tracking of climate change, deforestation, and ocean health on a macro scale.

Each type of instrumentation system plays a unique role in its respective field, contributing to advancements in industrial efficiency, healthcare, environmental conservation, and beyond. As technology evolves, these systems will continue to become more sophisticated, providing even greater insights and control across a wide range of applications.

Functionality and Applications of Instrumentation Systems

Instrumentation systems are pivotal in a wide array of applications, from industrial processes to healthcare monitoring, each tailored to specific requirements and objectives. Their functionality spans across monitoring, controlling, and diagnosing in various settings, ensuring operational efficiency, safety, and innovation.

Industrial Applications

In the industrial sector, instrumentation systems are the backbone of process control, playing a crucial role in automating and optimizing production lines. These systems monitor critical parameters such as temperature, pressure, flow rate, and chemical composition to ensure processes operate within desired parameters, enhancing efficiency and product quality. For instance, in the petrochemical industry, instrumentation systems control the refining process, ensuring the safe and efficient production of fuels and chemicals. In the food and beverage industry, they monitor conditions to ensure product consistency and compliance with health standards. The integration of instrumentation systems with industrial IoT (IIoT) technologies has further enhanced their capabilities, enabling predictive maintenance, real-time analytics, and remote monitoring, thus minimizing downtime and maximizing productivity.

Environmental Monitoring

Environmental monitoring systems are vital for assessing the health of ecosystems and the impact of human activities on the environment. These systems collect data on air and water quality, soil conditions, and wildlife populations, providing essential insights for conservation efforts and policy-making. For example, instrumentation systems that monitor air quality can detect and quantify pollutants like PM2.5, NOx, and SOx, informing strategies to reduce air pollution and protect public health. Water quality monitoring systems assess parameters such as pH, dissolved oxygen, and contaminant levels, ensuring safe drinking water and the health of aquatic ecosystems. Moreover, these systems play a critical role in climate research, tracking global temperature changes, greenhouse gas concentrations, and sea-level rise, contributing to our understanding of climate change and informing mitigation strategies.

Healthcare and Biomedical Applications

In healthcare and biomedical fields, instrumentation systems are essential for diagnosing, monitoring, and treating patients. These systems range from basic devices for measuring vital signs, such as blood pressure monitors and thermometers, to sophisticated imaging technologies like MRI and ultrasound scanners that provide detailed internal views of the body. Wearable technology has revolutionized patient monitoring, enabling continuous tracking of heart rate, glucose levels, and other vital parameters, facilitating early detection of potential health issues. In surgical settings, instrumentation systems such as laparoscopes and robotic surgical assistants enhance precision and reduce recovery times. Furthermore, research in biomedical instrumentation leads to the development of advanced prosthetics, artificial organs, and implantable devices, significantly improving the quality of life for individuals with disabilities or chronic conditions.

Aerospace and Automotive

In the aerospace and automotive industries, instrumentation systems are critical for ensuring the safety, performance, and reliability of vehicles and aircraft. In aviation, instrumentation systems provide pilots with essential information on aircraft speed, altitude, attitude, and engine performance, contributing to safe navigation and operation. Advanced avionics systems integrate GPS, radar, and communication systems, enhancing flight safety and efficiency. Similarly, in the automotive industry, instrumentation systems monitor engine parameters, vehicle speed, and fuel levels, while more advanced systems assist with navigation, collision avoidance, and autonomous driving. The integration of sensors and IoT technologies in vehicles enables predictive maintenance, improving vehicle reliability and lifespan. As the automotive industry moves towards electric and autonomous vehicles, instrumentation systems will play an even more significant role in managing battery systems, optimizing energy consumption, and ensuring safe and efficient operation.

Instrumentation systems are indispensable across various sectors, enhancing operational efficiency, ensuring safety, and fostering innovation. As technology advances, the scope and capabilities of these systems continue to expand, promising even greater contributions to industrial productivity, environmental sustainability, healthcare, and transportation.

Challenges and Considerations in Instrumentation Systems

Instrumentation systems, while invaluable across many sectors, face several challenges and considerations that can impact their effectiveness and reliability. Understanding these factors is crucial for the optimal design, implementation, and maintenance of these systems.

Accuracy and Precision

Accuracy and precision are paramount in instrumentation systems, as even slight deviations can lead to significant errors in data interpretation and decision-making. Accuracy refers to how close a measurement is to the true value, while precision denotes the consistency of repeated measurements. Factors affecting these metrics include sensor quality, signal interference, and the inherent limitations of measuring devices. Ensuring high accuracy and precision often requires sophisticated technology and design, increasing the complexity and cost of instrumentation systems.

Calibration and Maintenance

Regular calibration and maintenance are essential to retain the accuracy and reliability of instrumentation systems. Calibration involves adjusting the instrument to match a known standard or reference, ensuring that measurements remain true over time. However, the need for frequent calibration can be a logistical challenge, especially for systems in remote or harsh environments. Maintenance, while necessary to prevent failures and extend the lifespan of components, requires skilled personnel and can result in operational downtime, affecting productivity.

Environmental and Operational Challenges

Instrumentation systems must often operate in extreme or variable conditions, exposing them to challenges such as temperature fluctuations, humidity, vibration, and corrosive substances. These environmental factors can degrade components, distort measurements, and lead to system failures. Designing systems that can withstand such conditions without compromising performance requires advanced materials and engineering, adding to the complexity and cost. Additionally, in highly integrated systems, a single point of failure can disrupt the entire operation, necessitating robust redundancy and fail-safe mechanisms.

Conclusion

Instrumentation systems are indispensable in modern industry, healthcare, environmental monitoring, and numerous other fields, offering precise control and measurement capabilities that enhance efficiency, safety, and innovation. However, achieving and maintaining the high levels of accuracy and precision demanded by these applications present significant challenges. Regular calibration and maintenance are essential to ensure ongoing reliability, while environmental and operational conditions impose stringent requirements on system design and materials. As technology advances, addressing these challenges will require innovative solutions, including more robust materials, advanced signal processing techniques, and intelligent self-diagnostic capabilities. Despite these hurdles, the continued evolution of instrumentation systems promises to expand their capabilities and applications, driving progress across a wide array of disciplines.

Automation System

Automation System  Energy Engineeing

Energy Engineeing  Instrumentation System

Instrumentation System  Mechanical Engineeing

Mechanical Engineeing  Piping Technologies

Piping Technologies  Transportations

Transportations  Manufacturing

Manufacturing  Training Material

Training Material