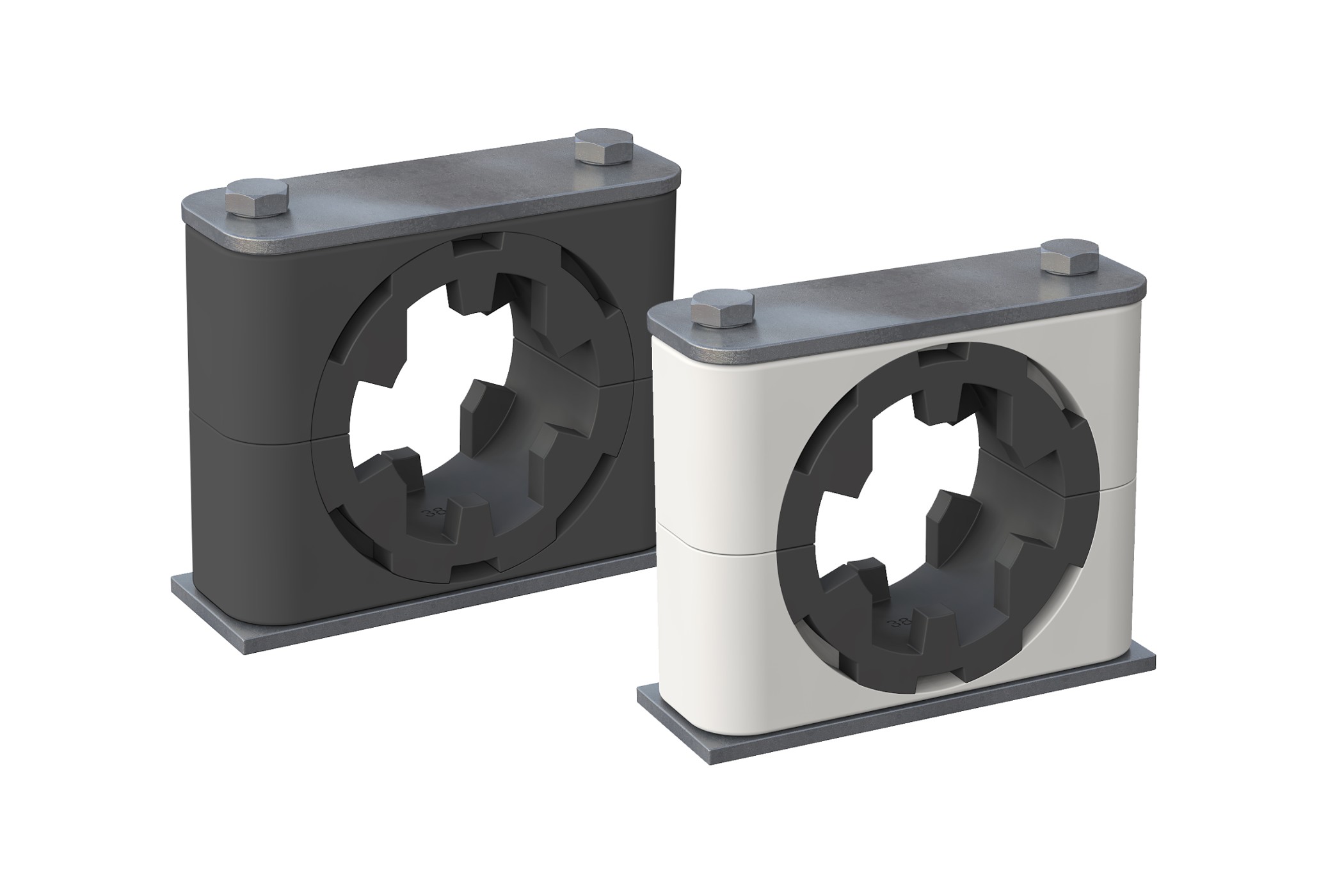

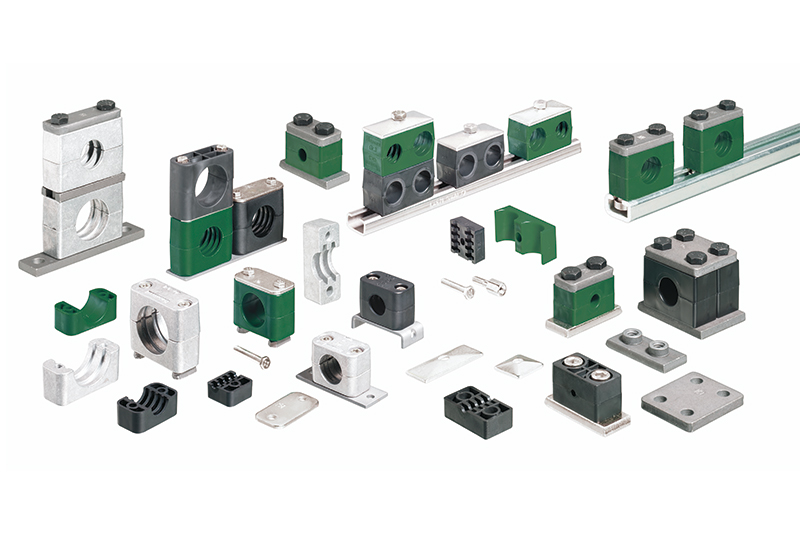

Tube Clamp Overview : Types of Tube Clamps

Contents

I . Introduction to Tube Clamps

Contents1 Understanding Compressed Air Dryer1.1 Definition and Function of Compressed Air Dryer1.1.1 Consequences of Moisture in Compressed Air Systems2 Types of Compressed Air Dryers2.1 Refrigerated Dryers2.2 Desiccant Dryers2.3 Membrane Dryers2.4 Deliquescent Compressed Air Dryer2.4.1 Comparison and Selection Criteria3 Key Components and Design of Compressed Air Dryer3.1 1. Air-to-Air Heat Exchangers3.2 2. Air-to-Refrigerant Heat Exchangers3.3 3. […]

Contents1 What is a fusible plug?2 What is fusible plug used for?3 Components of what is a fusible plug4 How does fusible plug work?5 Types of fusible plug6 What temp does a fusible plug melt at ?7 A fusible plug is made from8 Applications of fusible plug9 Conclusion What is a fusible plug? A fusible […]

Contents1 What is a Oxygen Regulator?2 Types of Oxygen Regulators2.1 Flow Regulators2.2 Pressure Regulators2.3 Demand Regulators2.4 Integrated Regulators2.5 Comparison and Specific Use-Cases3 Components of oxygen regulator4 How Oxygen Regulators Work4.1 Basic Principles of Operation4.2 Detailed Mechanism4.3 Materials and Manufacturing4.4 Gauges and Controls5 Applications of Oxygen Regulators5.1 Medical Applications5.2 Industrial Applications5.3 Aviation and Space Exploration5.4 Scuba […]

Contents1 Introduction1.1 Definition and Basic Understanding1.2 Brief History and Evolution1.3 Types of Oxygen Cylinders1.3.1 Medical Oxygen Cylinders1.4 Industrial Oxygen Cylinders1.4.1 Portable Oxygen Cylinders2 Components and Functionality of Oxygen Cylinders2.0.1 Anatomy of an Oxygen Cylinder2.0.2 Storage and Pressurization2.0.3 Safety Features3 Safety Protocols for Oxygen Cylinders3.1 Handling and Transportation3.2 Storage Conditions3.3 Contamination Prevention3.4 Emergency Procedures4 Inspection and […]

Contents1 1. What is a flow meter?1.1 Understanding Flow Measurement2 2. Types of Flow Meters2.1 2.1 Mechanical Flow Meters2.2 2.2 Electronic Flow Meters2.3 2.3 Mass Flow Meters2.4 2.4 Open Channel Flow Meters3 3. Selection Criteria for Flow Meters3.1 3.1 Fluid Characteristics3.2 3.2 Accuracy Requirements3.3 3.3 Installation Environment3.4 3.4 Cost Considerations4 4. Applications of Flow Meters4.1 […]

Contents1 What is Pressure Gauge?2 Types of Pressure Gauges2.1 1. Mechanical Pressure Gauges:2.2 2. Electronic Pressure Gauges:2.3 3. Specialty Gauges:3 How Pressure Gauges Work3.1 How Pressure Gauges Work (Mechanical Aspect)3.2 How Pressure Gauges Work (Electronic Aspect)4 Materials and Design5 Pressure gauge selection criteria5.1 1. Measurement Range and Scale5.2 2. Accuracy Requirements5.3 3. Process Media Compatibility5.4 […]

Contents1 What is Vacuum Tubing ?1.1 Characteristics:1.2 Vacuum Tubing Uses:2 Types of Vacuum Tubing3 What is the function of vacuum tubing?3.1 1. Creating and Maintaining a Vacuum Environment:3.2 2. Connecting Vacuum Components:3.3 3. Transporting Substances Under Vacuum Conditions:3.4 4. Protecting Sensitive Processes:3.5 5. Facilitating Vacuum-Based Manipulations:3.6 6. Isolating Vibrations and Thermal Transfers:3.7 7. Enabling Vacuum-Based […]

Contents1 What is tubing bender?2 Types of Tubing Benders2.1 Manual Tubing Benders2.2 Hydraulic Tubing Benders2.3 Mechanical Tubing Benders2.4 Electric Tubing Benders2.5 CNC Tubing Benders2.5.1 Comparison and Use Cases3 Applications of Tubing Benders3.1 Automotive Industry3.2 Plumbing and HVAC3.3 Aerospace and Defense3.4 Manufacturing and Metalworking3.5 Specialty Applications4 How Tubing Benders Work4.0.1 Basic Principles of Tube Bending4.0.2 Differences […]

Contents1 What is pressure regulator valve?2 Components of pressure regulator valve3 Working principle of pressure regulator valve4 Types of pressure regulator valve5 Applications of pressure regulator6 Pressure Effect of pressure regulator6.1 Downstream Pressure Control:6.2 Upstream Pressure Influence:6.3 Overall System Impact:7 Pressure regulator valve sizing7.1 Steps for Sizing:8 Pressure regulator valve selection criteria9 Conclusion What is […]

Contents0.1 What is a flange ?0.2 Types of flange0.3 Flange classifications0.4 Pressure class of each type of flange0.5 How to measure flange size0.5.1 1. Nominal Pipe Size (NPS)0.5.2 2. Flange Diameter (OD)0.5.3 3. Bolt Circle Diameter (BCD)0.5.4 4. Number of Bolt Holes0.5.5 5. Bolt Hole Diameter0.5.6 6. Thickness0.5.7 7. Flange Face Type0.5.8 Additional Tips0.6 Flange […]

Automation System

Automation System  Energy Engineeing

Energy Engineeing  Instrumentation System

Instrumentation System  Mechanical Engineeing

Mechanical Engineeing  Piping Technologies

Piping Technologies  Transportations

Transportations  Manufacturing

Manufacturing  Training Material

Training Material